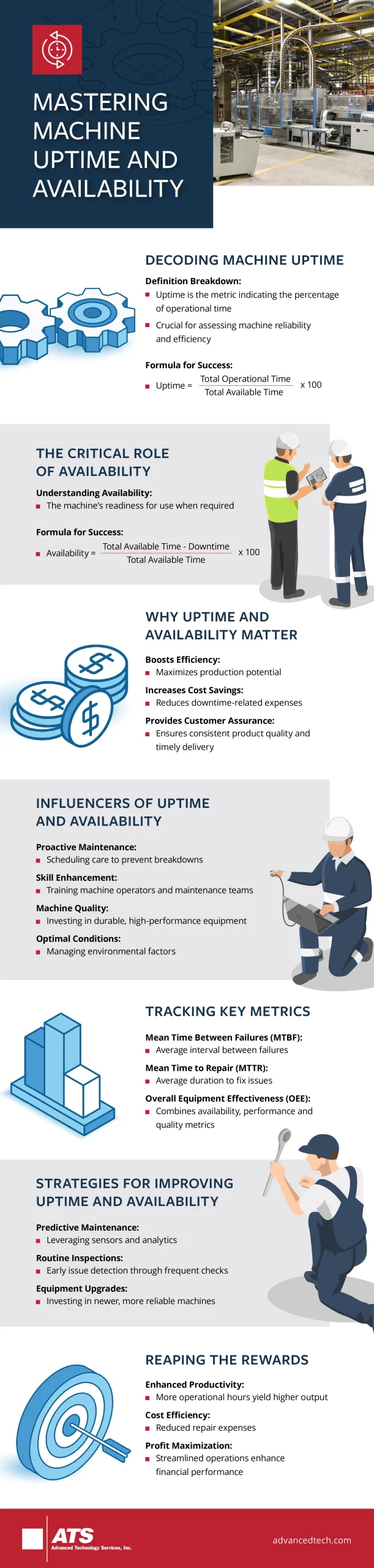

Key Practices for Maximizing Machine Uptime and Availability

In the manufacturing and industrial sectors, machine uptime and availability are critical to ensuring productivity and operational efficiency. Implementing effective strategies to improve these metrics can drive business success.

Machine uptime reflects the proportion of time machinery is operational and running as expected. It serves as a key measure of equipment reliability. Achieving high uptime involves consistent maintenance, skilled operators, and reliable equipment that minimizes interruptions and ensures smooth production.

Availability is a broader concept that includes uptime but also evaluates whether equipment is ready for use when required. This metric ensures that machinery remains accessible, avoiding production delays caused by unavailability.

High uptime and availability deliver significant benefits, such as minimizing repair costs, reducing downtime, and increasing production output. Reliable equipment also enhances product quality and supports timely deliveries, improving customer satisfaction.

One of the most effective strategies for improving uptime is preventive maintenance. By conducting regular inspections and servicing, potential failures in mro parts can be detected early and addressed before they disrupt operations. Skilled operators and maintenance staff are essential for quickly identifying and resolving issues.

Investing in high-quality equipment is another way to enhance performance. Reliable machines reduce the risk of breakdowns and often include features that simplify maintenance. Environmental factors, such as temperature, humidity, and cleanliness, should also be managed to maintain peak operating conditions.

Metrics like Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) provide insight into machine performance. MTBF measures reliability by tracking the average time between failures, while MTTR evaluates how quickly equipment can be repaired and returned to service.

Adopting predictive maintenance takes machine performance to the next level. This data-driven approach uses sensors and analytics to forecast potential failures, enabling timely interventions. Equipment upgrades, regular inspections, and training programs for operators are additional methods for ensuring high uptime and availability.

In conclusion, focusing on machine uptime and availability is essential for achieving cost-effective and efficient operations. Businesses that prioritize maintenance, invest in quality equipment, and train skilled personnel will see increased productivity and enhanced customer satisfaction.