Errors that must be avoided while outsourcing manufacturing

In many industries, employing contract manufacturers to complete the production of spare parts is often a modern need. With many companies that cut costs by getting rid of in-house production, they often switch to manufacturing specialist companies to carry out this work for them.

This can be a good idea – there are many benefits of this kind of setting, including significant cost savings, better quality spare parts and a faster production process. However, there are some traps that really need to be avoided while working with contract manufacturers; Here are some errors that must be avoided.

The first problem that arises works with the wrong type of contract manufacturer, because this can produce a lower product, an inefficient production process and a number of communications, administrative management.

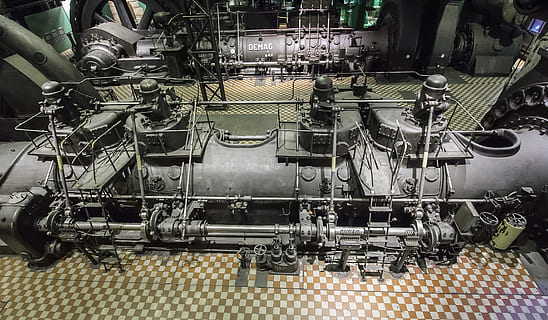

It is important to ensure that the company you are professional, has a reputation, and has a strong trace record from producers of spare parts for companies that are similar to you in nature. If you are looking for an eccentric shaft manufacturer, then make sure that the company you choose has a broad extensive experience of producing these types of parts.

Many companies will also specialize in certain sectors, such as industrial industries, motorbikes and aerospace and more. Finding specialists in your sector is another idea that is very wise.

It is also important to ensure that contract manufacturers will be able to meet your needs in terms of quality and quantity; Think of outsourcing companies as an extension of your own, because basically it will play this section.

Another error you have to really avoid the manufacture does not put in an adequate project management place, because it is important when taking the project together with contract manufacturers. As mentioned above, you basically hire manufacturers as an extension of your own company, and therefore project management you need to be harmonized.

The successful project management key is clear and open communication between the two companies, and for this there is a plan to be done so that there is no information that is passed between the team working on the project, as well as the lack of information communicated on important points throughout the project.

Another problem that can arise with contract manufacturing is that the cost is unclear, which is a clear area that needs to be clearly defined at the beginning of each project. Problems are present at many different levels, from initial quotes to hidden fees that may arise during the process.

The general example of this is that many companies choose to outsource their manufacturing abroad, using silver or eccentric shaft manufacturers in foreign countries that do not fully consider costs and problems that will arise in connection with certain production standards, along with the problem of transportation and culture many arise.

While offshore production can be attractive with cheap labor promises in several countries compared to others, this can be a fake economy for certain companies, and in all cases is absolutely necessary for factors in various costs that will occur with a foreign contract manufacturer.

Other financial concerns present when working with any contract manufacturers – whether the bottom of the sea, ceramic core tools or eccentric shaft manufacturers – are clear pricing structures. The truth is that, when the manufacturing component varies specifications in various timescales, pricing structures can run away.